Showing 1–12 of 56 results

-

Use of air-cooled chiller:

▲ The chiller is used for cooling the plastic processing machinery molding mold, which can greatly improve the surface finish of plastic products, reduce the surface wrinkles and internal stress of plastic products, make the products not shrink and deform, facilitate the demolding of plastic products, speed up the product shaping, and greatly improve the productivity of the plastic molding machine.

-

▲ The parts contacted by the raw materials are made of stainless steel (or rubber tube) materials to keep the raw materials pure

▲ Configure dust collection device to absorb dust and prevent air pollution

▲ It is convenient to disassemble and clean

-

Features of blade plastic crusher;

1. All steel welded base, solid and durable.

2. Easy to disassemble design, easy to clean and maintain.

3. Imported steel tool, sharp blade, easy to replace, durable.

4. It is easy to smash all kinds of soft and hard plastics.

-

Uses of box dryer:

▲ The box dryer is widely used for drying any plastic materials, and can also dry materials of different materials and colors at the same time.

▲ It is especially suitable for drying materials with high-temperature accuracy requirements, low consumption, and various colors

▲ It is also suitable for preheating or drying in dry food, pharmaceutical, electronic electroplating, and other industries.

-

▲High-temperature series can cool down to 25 ℃, which is suitable for water circulation with high dry inlet water temperature

▲The whole tower has strong stability, can withstand Richter 8 vibration, and wind resistance can reach 12 levels

-

Features of claw knife plastic crusher

1. All steel welded base, solid and durable.

2. Easy to disassemble design, easy to clean and maintain.

3. Imported steel tool, sharp blade, easy to replace, durable.

4. It is easy to smash all kinds of soft and hard plastics.

-

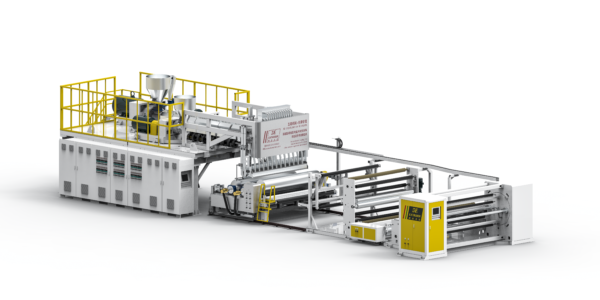

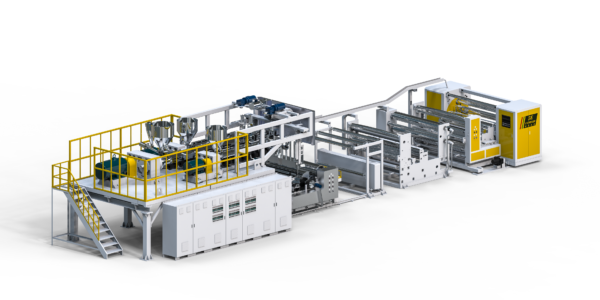

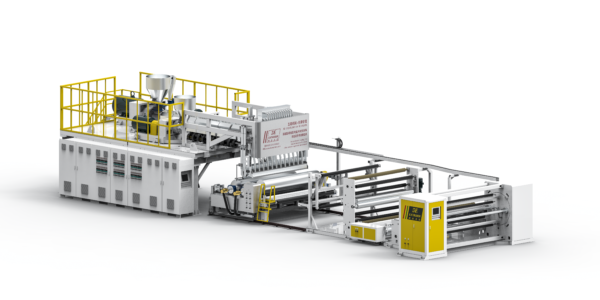

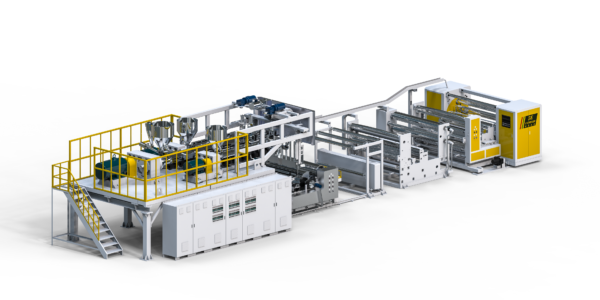

1. Two or more extruders realize coextrusion. The multilayer composite film directly prepared by one-step processing has the advantages of less production process, less energy consumption, and low cost

2. Complete machine PLC control and touchscreen operation

3. The latest designed winding tension control unit ensures accurate, stable, and reliable tension measurement and control

-

▲The screw is designed with a special mixing function and high plasticizing capacity and is matched with a European static mixer to ensure good plasticization, good mixing effect, and high output

▲Online auto film-thickness measurement and automatic die-head adjusting, imported Europe cooling forming roll is optional, the special spiral runner design ensures good film cooling and shaping effect at high speed

-

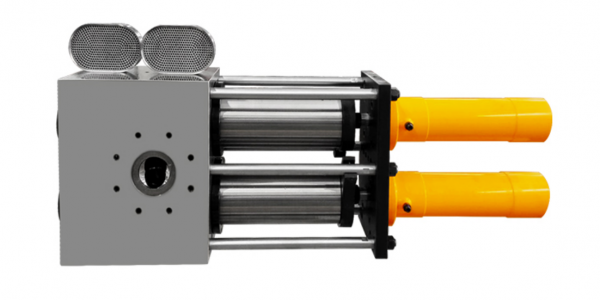

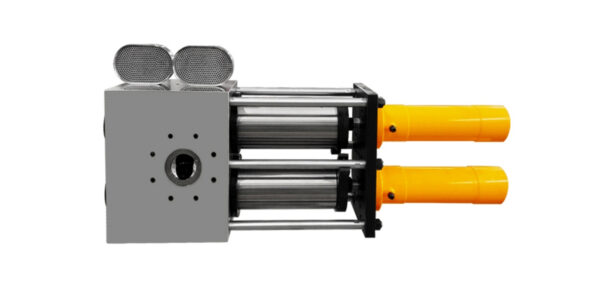

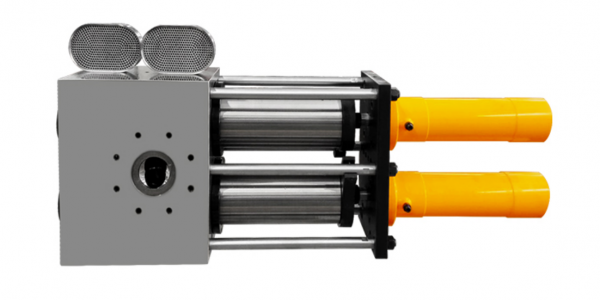

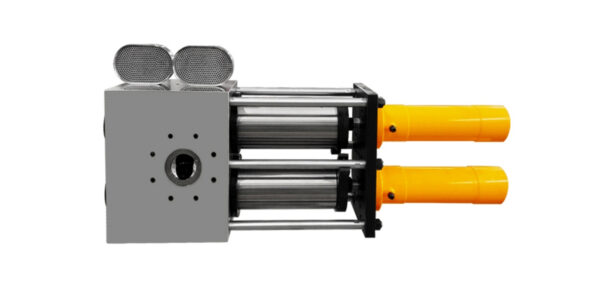

Features: plane sealing design; Stainless steel outer tube; Complete and uniform circulation design; Maximum bearing spacing; Threaded and quick flange-changing connection form of outer pipe

-

The double column single station hydraulic screen changer is suitable for the production of high-pressure products, especially for almost all thermoplastics such as blown film, cast film, wire drawing, and plastic granulation.

-

The double column single station hydraulic screen changer is suitable for the production of high-pressure products, especially for almost all thermoplastics such as blown film, cast film, wire drawing, and plastic granulation

-

The eco-friendly dryer is widely used for drying any plastic materials. It can dry raw materials that are wet due to packaging, transportation or recycling. The stainless steel barrel can be directly used for drying plastic materials such as injection molding machines, extruders, granulators, etc.

End of content

End of content