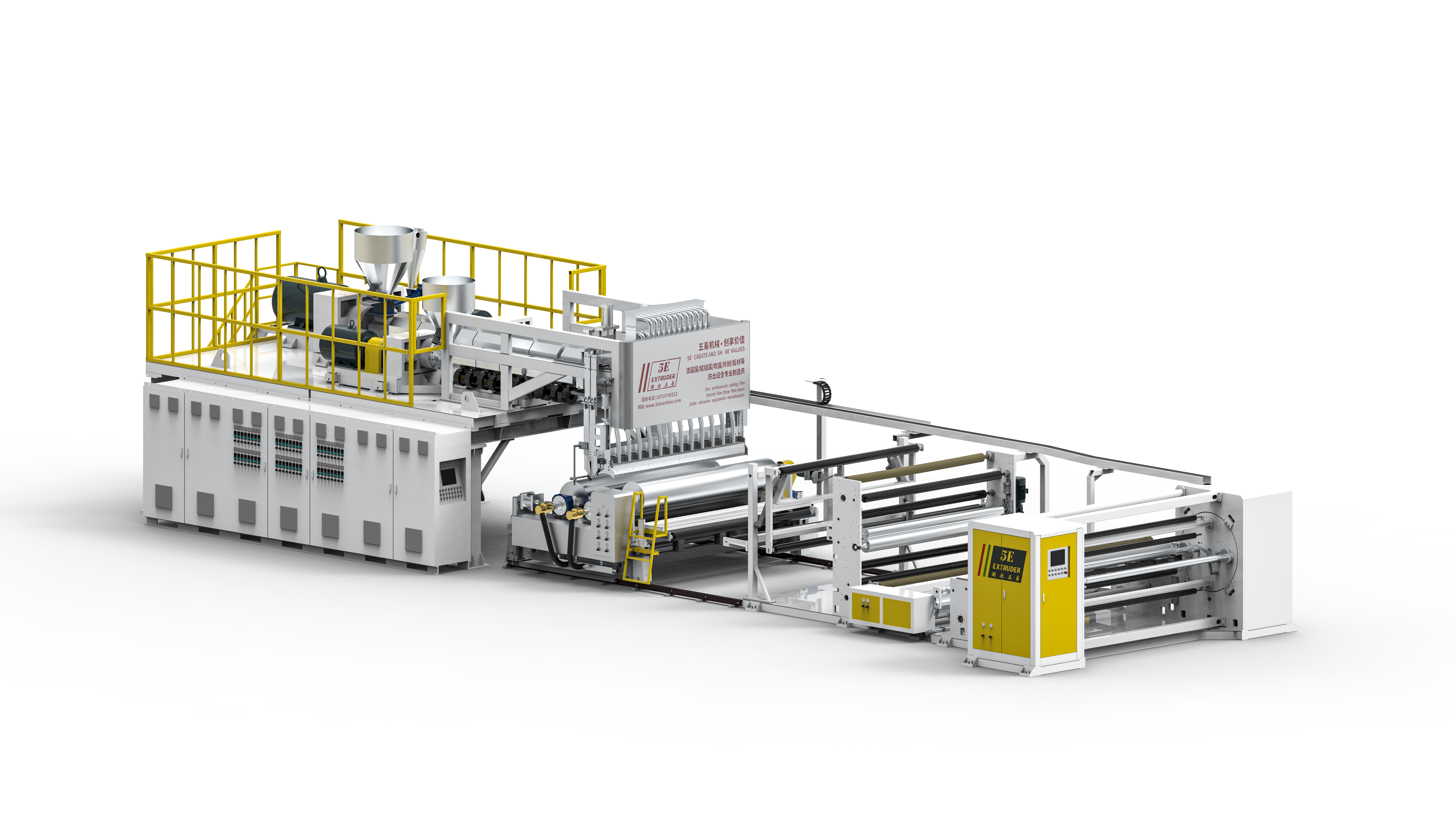

CPE Cast Film Line

1. Two or more extruders realize coextrusion. The multilayer composite film directly prepared by one-step processing has the advantages of less production process, less energy consumption, and low cost

2. Complete machine PLC control and touchscreen operation

3. The latest designed winding tension control unit ensures accurate, stable, and reliable tension measurement and control

描述

Machine Application

The CPE Co-extrusion line mainly uses linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), high-density polyethylene (HDPE), and ethylene vinyl acetate copolymer (EVA) as the main raw materials. It can produce an embossed film, high-grade non-woven composite film and paper surface-coated film, and other products

CPE Film Features

1. The film made by the multi-layer co-extrusion casting method can make a variety of materials with different characteristics compound with each other in the extrusion process, so that the products have the excellent characteristics of different materials and can complement each other in characteristics so that the products can obtain the properties and appearance that are specially required, such as anti-itching and moisture resistance, impermeability, transparency, fragrance retention, heat preservation, UV protection, pollution resistance, Low-temperature heat sealing and strength, stiffness, hardness, and other mechanical properties

2. Thinner, better thickness uniformity, Good transparency, and heat-sealing performance, Good internal stress performance, and good printing effect.

CPE Film Application

1. Hygiene articles: medical surgical clothes, disposable bed sheets, sanitary napkins, baby diapers, pet pads, shoe covers, head covers, etc

2. Daily necessities: various tablecloths, gloves, aprons, shower curtains, suit covers, raincoats, beach clothes, chair covers, wardrobe covers, blankets, etc

3. Packaging of industrial products: cover of typing machine, computer, air conditioner, photocopying machine, and dust cover of various machines

Specifications

| Model | 5ECPE75/110/75-2000 | 5ECPE80/120/80-2500 | 5ECPE90/125/90-3000 | 5ECPE90/120/120/90-3500 |

| Finished-fill width | 1500mm | 2000mm | 2500mm | 3000mm |

| Transparent film thickness | 0.03-0.15mm | 0.03-0.15mm | 0.03-0.15mm | 0.03-0.15mm |

| Embossed film thickness | 0.03-0.30mm | 0.03-0.30mm | 0.03-0.30mm | 0.03-0.30mm |

| Max extruding capacity | 300kgs/h | 400kgs/h | 500kgs/h | 800kgs/h |