-

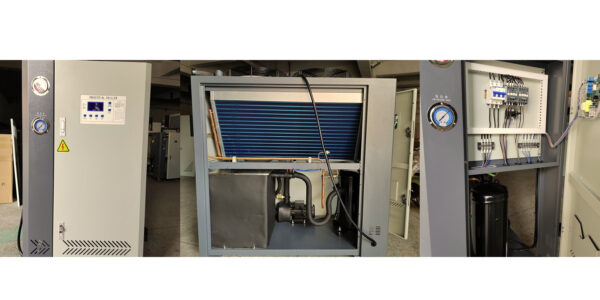

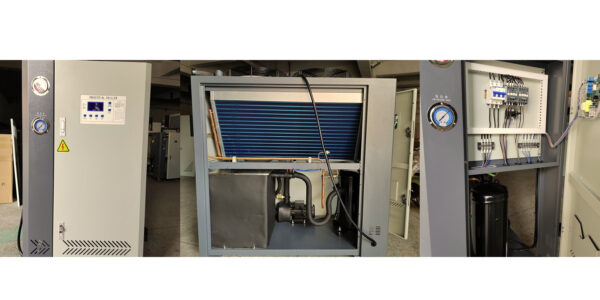

Use of air-cooled chiller:

▲ The chiller is used for cooling the plastic processing machinery molding mold, which can greatly improve the surface finish of plastic products, reduce the surface wrinkles and internal stress of plastic products, make the products not shrink and deform, facilitate the demolding of plastic products, speed up the product shaping, and greatly improve the productivity of the plastic molding machine.

-

▲ Oil temperature machine is applicable to injection molding, precision injection molding mold temperature control, extrusion molding temperature control, runner heating temperature control, and rubber, and plastic machinery temperature control.

▲ With complete specifications, water, and hot oil can be selected as the heat transfer medium, and suitable models can be selected according to the required temperature.

-

The application of the screw chiller to the cooling of the plastic processing machinery molding mold can greatly improve the surface clarity of the plastic products, reduce the surface wrinkles and internal stress of the plastic products, make the products not shrink and deform, facilitate the demolding of the plastic products, accelerate the product shaping, and greatly improve the production efficiency of the plastic molding machine.

-

- Injection molding, precision injection molding mold temperature control, extrusion molding temperature control, wheel force heating temperature control, rubber, and plastic brain mechanical temperature control.

- With complete specifications, water, and hot oil can be selected as the heat transfer medium, and suitable models can be selected according to the required temperature.

-

A water-cooled chiller is used for cooling the plastic processing machinery molding mold, which can greatly improve the surface finish of plastic products, reduce the surface wrinkles and internal stress of plastic products, make the products not shrink and deform, facilitate the demolding of plastic products, speed up the product shaping, and greatly improve the productivity of the plastic molding machine.

End of content

End of content