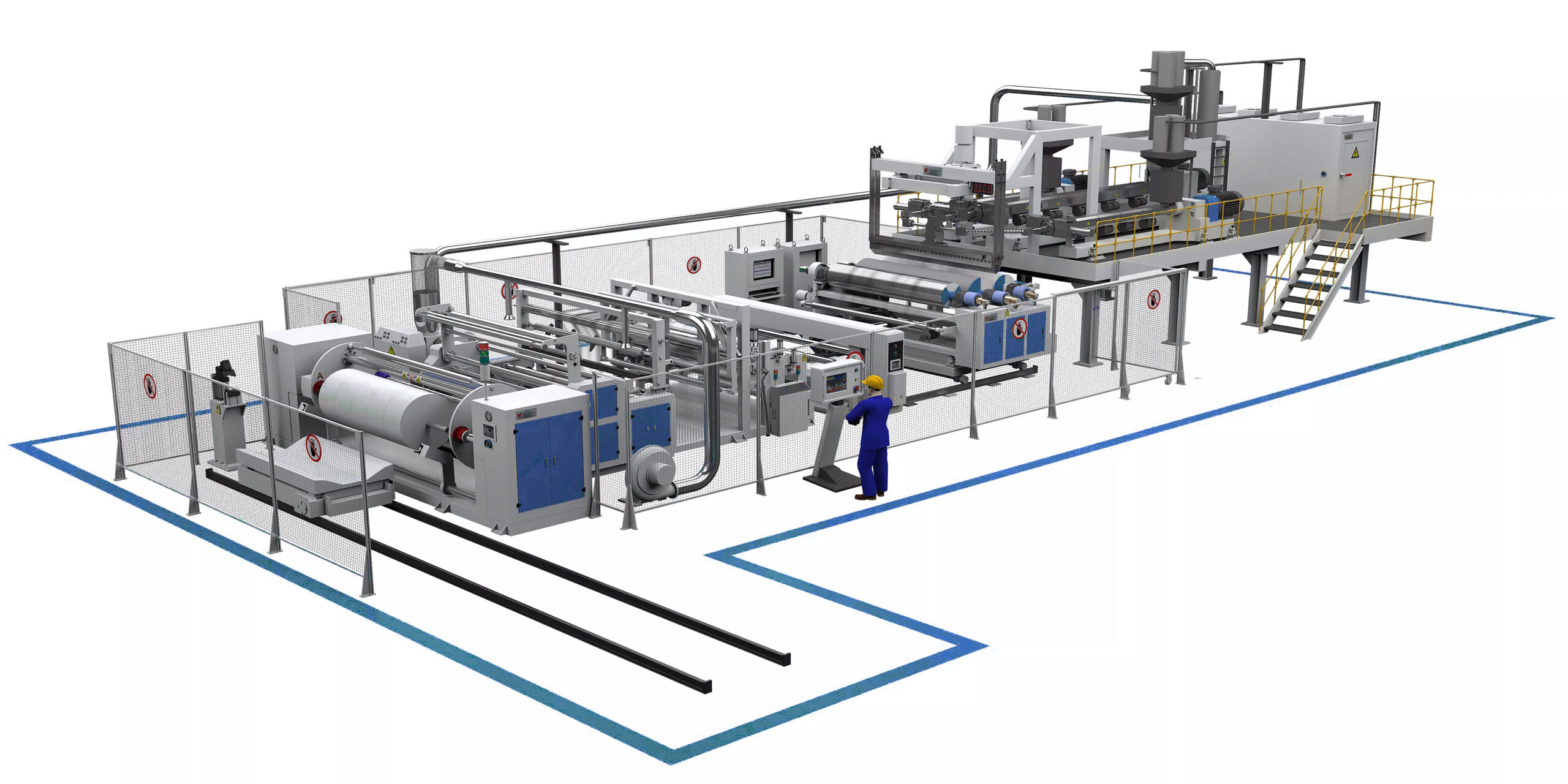

Strech Film Line

- Full-auto loading and unloading device

- Fully automatic paper tube loading and unloading device realizes truly automatic operation

- The temperature control adopts a full microcomputer and touch screen for precise temperature control

Description

The stretch film extrusion line is mainly applicable to the production of LLDPE, LDPE, HDPE, PE, and other cast films. The line uses an advanced intelligent industrial control system, with the concealed automatic cutter, automatic material breaking, automatic roll changing, and automatic paper tube loading and unloading device, to ensure safe and convenient operation, more solid and smooth winding, and ensure product quality. The production efficiency is greatly improved, the production cost is reduced, and greater value is created. The auxiliary machine is equipped with a swing device to improve the flatness and appearance quality of the stretch wrap, making the product more competitive

Optional Item

1. Vacuum box

2. Full-auto adjusting die

3. Full-auto hydraulic screen changer

4. Full-auto or Semi-auto thickness measurement

5. Melt pump and PID control system

Specifications

| Model | 5EPE55/75-1250 | 5EPE65/90/65-1850 | 5EPE65/100/80-2400 | 5EPE80/120/80-2400 |

| Screw diameter | 55/75mm | 65/90/65mm | 65/100/80mm | 80/120/80mm |

| Screw L/D | 30:1 | 30:1 | 30:1 | 32:1 |

| Screw speed | 50-150rpm | 50-150rpm | 50-150rpm | 50-150rpm |

| Film width | 1000mm/2x500mm) | 1500mm/3x500mm | 2000mm/4x500mm | 2000mm/4x500mm/4x450mm |

| Heating power | 75KW | 180KW | 220KW | 300KW |

| Film thickness | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm |

| Production Capacity | 75-150kg/h | 150-280kg/h | 200-400kg/h | 250-500kg/h |

| Film-layer structure | AB/ABA | ABC/ACBCA | ABC/ACBCA | ABC/ACBCA |

| Machine Gross Weight | 9T | 15T | 16T | 20T |

| Dimension L*W*H(mm) | 8500x3500x3400 | 12500x5500x4600 | 14000x5500x4800 | 16500x6500x5000 |